PHOTOVOLTAIC POWER STATION

Brief introduction and history of the company:

- Design and manufacturing of various single- and multi-stage forging dies (preform and form) for parts ranging from 200 grams to 30 kilograms

- Precision machining (light and heavy), heat treatment, and manufacturing of various hydraulic jacks

- Sheet metal work, forming, punching, cutting, welding, and fabrication of various structures, tanks, and precision frameworks

- Sharp automation systems

- Conveyor sprockets

- Overhead conveyor chains

- Paint curing ovens

- Paint booths

Some Projects, Experiences, and Capabilities:

- Reverse engineering and fabrication of standard 20-foot and 40-foot container prototypes

- Fabrication of 32-meter telescopic towers for high-voltage power transmission

- Construction of rotary kiln bodies and heat treatment furnaces

- Reverse engineering and manufacturing of airless pumps for paint lines and fluid transfer

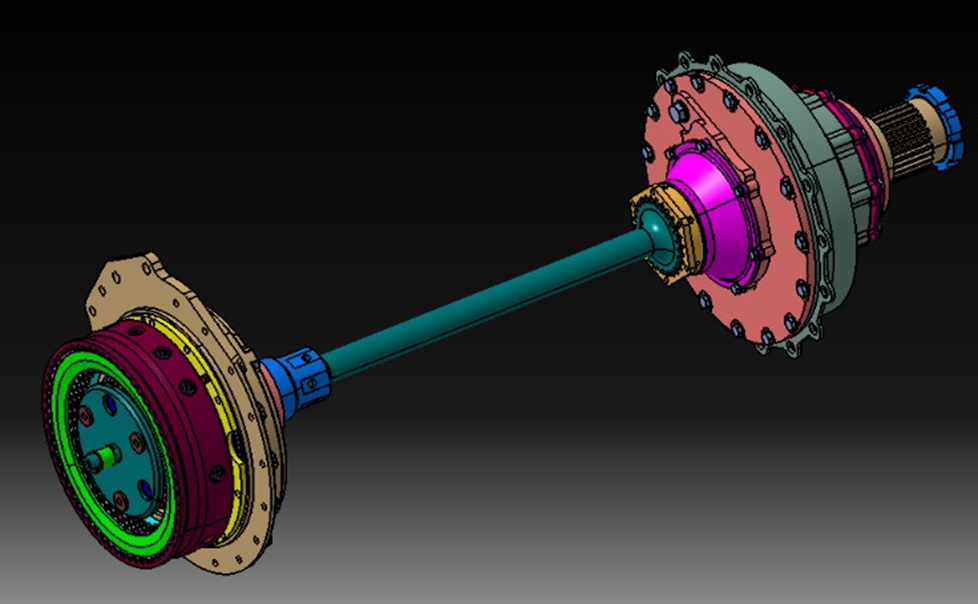

- Reverse engineering, analysis, and simulation of the gearbox and final drive assembly of a tracked construction vehicle

- Design, construction, and installation of material handling conveyor belts

- Construction and installation of various industrial sheds (steel structures)

- Machining of gearbox housings and parts for wagons and locomotives

- CNC and conventional machining of various light and heavy components

- Fabrication of clutch and brake pedal systems for Pride vehicles

- Design and manufacturing of various forging dies

- Manufacturing of various hydraulic jacks